Select a vehicle to find exact fit parts

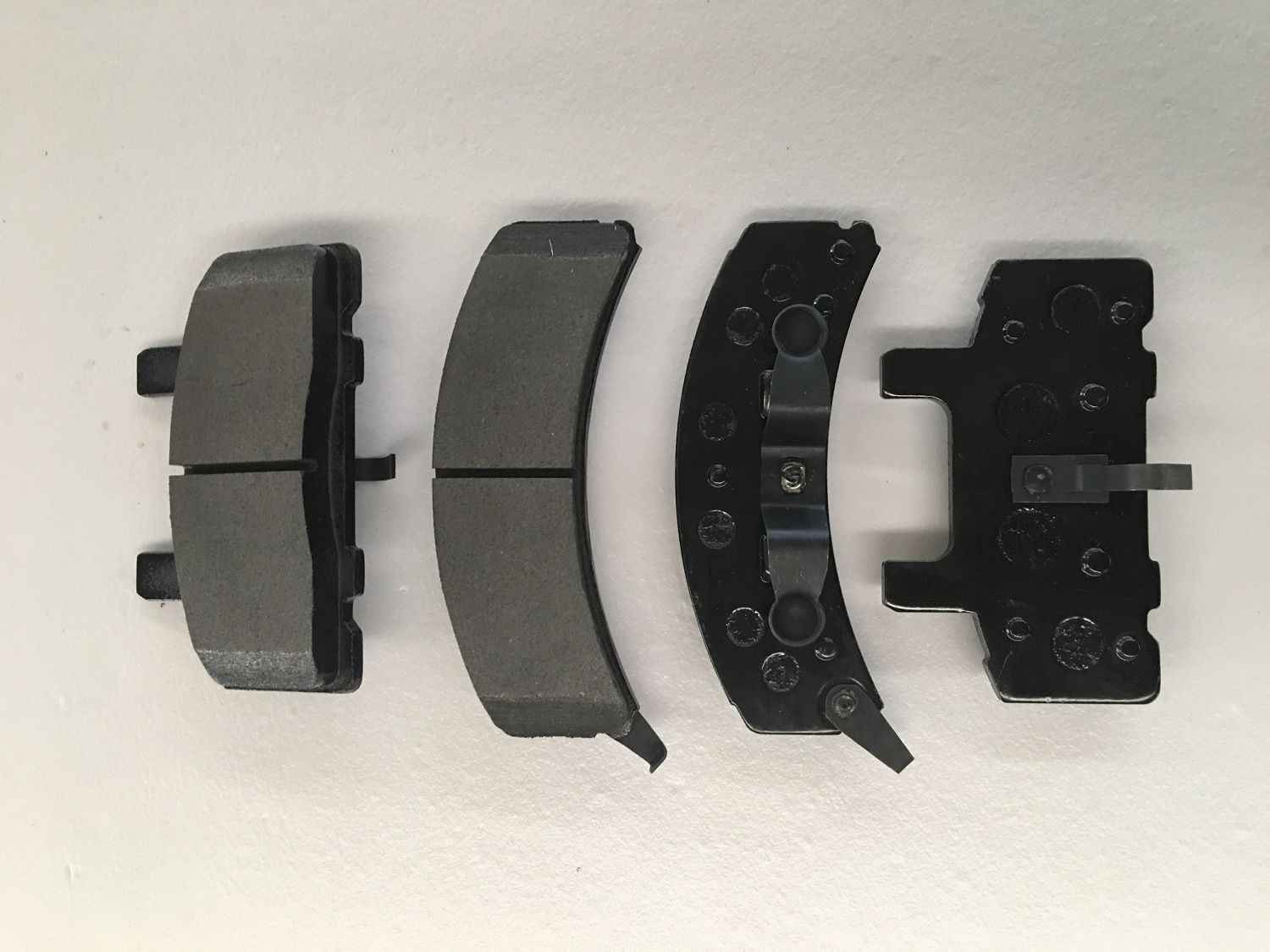

Front Ceramic Brake Pads

- Ceramic Brake Pads provide the ultimate in comfort, smooth stopping performance and superior noise control for late model vehicles.

- Ceramic formulations reduce heat generation, cool down quickly, and consistently outperform the competition.

- Scorching is a key element of manufacturing our Ceramic Positive Mould Disc Brake Pads. Scorching provides the initial phase of disc brake pad break-in.

- Lab test 60,000 KM. Fabric rubber coated shims, slotted and chamfered.

- ISO/TS 16949 certified. Reliable design and production. Each unit is tested for 100% performance first class quality.

Related products

-

- Materials meet SAE specifications

- ISO/TS 16949 certified

- Rotor Runout Test is all less than 10, great balance

- Proforce Brake Rotors are manufactured to OE specifications

-

- Ceramic Brake Pads provide the ultimate in comfort, smooth stopping performance and superior noise control for late model vehicles.

- Ceramic formulations reduce heat generation, cool down quickly, and consistently outperform the competition.

- Scorching is a key element of manufacturing our Ceramic Positive Mould Disc Brake Pads. Scorching provides the initial phase of disc brake pad break-in.

- Lab test 60,000 KM. Fabric rubber coated shims, slotted and chamfered.

- ISO/TS 16949 certified. Reliable design and production. Each unit is tested for 100% performance first class quality.

-

- Powder coating to fight against rust; anti erosion

- Materials meet SAE specifications

- ISO/TS 16949 certified

- Rotor Runout Test is all less than 10, great balance

- Proforce Brake Rotors are manufactured to OE specifications

-

- Powder coating to fight against rust; anti erosion

- Materials meet SAE specifications

- ISO/TS 16949 certified

- Rotor Runout Test is all less than 10, great balance

- Proforce Brake Rotors are manufactured to OE specifications